The best heating performance from pellet heating technology.

Integrated hydraulic modules (Nano-PK)

The heat circuit/boiler pump, the buffer charge pump/circulation pump and all pipework can be implemented in the boiler, easily accessible and ready for connection. There are 2 different modules to choose from.

Highest efficiency in the entire utilisation range

With its uniquely high efficiency, the Hargassner pellet heating system not only spoils you with the most economical fuel consumption, but also the environment with the lowest emissions!

5 years warranty

2 or 5 years material warranty depending on the boiler type on electrical components and gear motors. 2-year full warranty (material, labour and travel costs) on all parts of the system.

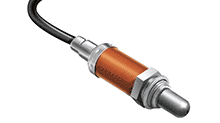

The lambda sensor with fuel quality detection

The lambda sensor regulates the exact right amount of fuel in each output range, depending on the quality of the wood chips or pellets. This is the only way to guarantee optimum, i.e. economical and low-emission combustion, which also saves you energy and money with an increase in efficiency!

The Lambda Touch Tronic

Features an exceptional, above-average design and simple operation. It controls the entire heating system from combustion to buffers, heat circuits and boilers.

The Hargassner App

Easily and quickly make changes to your heating system from anywhere or call up information around the clock. User-friendly interface, switch heat circuits on & off, change heating times & temperatures, etc….

Negative pressure in the boiler

An induced draught fan on the extraction pipe ensures optimum air draught in the Hargassner pellets heating system. System advantage: High operational reliability due to constant negative pressure independent of the chimney draught.

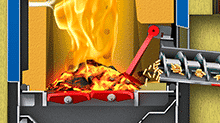

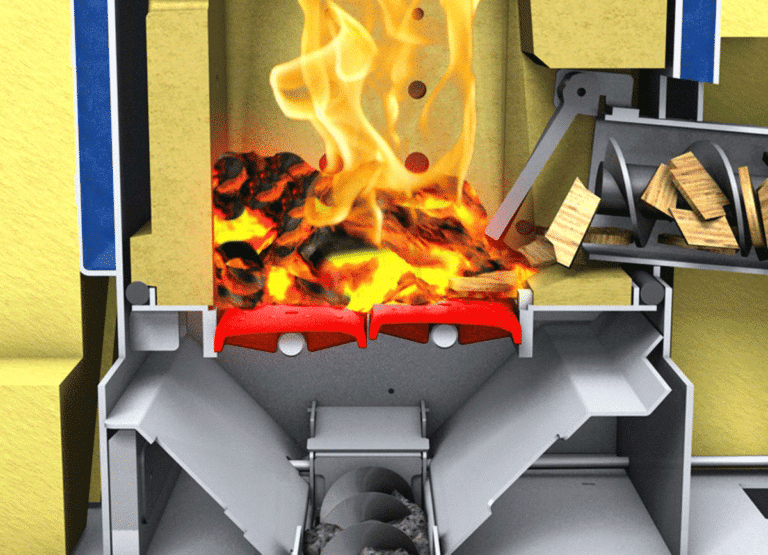

Circulation zone for complete post-combustion

Particles entrained from the combustion chamber are returned to the main flame in the circulating gas flow, ensuring complete post-combustion.

Fully refractory-lined high-temperature combustion chamber

Fireclay has proven to be the best material in terms of heat storage capacity, durability and function: The high combustion chamber temperature at full and low load contributes to the high efficiency and lowest emissions.

Automatic sliding grate

With the Hargassner pellet boiler, the grate cleans itself automatically and thus transports the fire residues into the ash pan. Primary air is drawn in via the grate and ignition is automatic via an energy-saving ceramic ignition system.

Ash extraction into the box (Nano-PK 32)

An ash screw below the sliding grate fills the box to the last corner, making very long emptying intervals possible.

Automatic ash pan level indicator on the display

The remote control and mobile terminals indicate when the ash pan needs to be emptied. A filling reserve then gives you about another week. This ensures that the ash pan is not overfilled and that you still have a clean boiler even years later.

"Air transport" up to approx. 20 m!

The Hargassner pellet suction turbine sucks the pellets from the discharge screw into the storage hopper. Up to a hose length of approx. 20m, structural obstacles between the heating room and the storage room can thus be overcome without any problems.

Cleaning the boiler? The engine does it automatically

Gone are the days of cleaning the boiler: depending on the heating time, the automatic boiler cleaning system switches on and frees the boiler walls from fly ash residues that fall directly into the ash pan. They no longer have anything to do with cleaning.

From the storage hopper into the double dosing valve

After automatic filling of the storage hopper up to the level indicator – the suction turbine is switched off when the hopper is full. Via the double-cell wheel metering sluice, the pellets fall into the feed screw, which transports them directly into the combustion chamber.

Pellets Low-temperatur boiler up to 38°C (Nano-PK)

The outdoor temperature control enables the control unit to adjust the output and boiler temperature to the temperature demand. The usable range for the Nano-PK extends from 38 to 75°C. Only as much energy/temperature is generated as is actually required.

Energy saving ignition

Due to the innovative design of this ignition element, on the one hand the power consumption could be reduced to only 300 W (by up to 1000 W less) and on the other hand the effectiveness of the ignition process could be increased. – Energy savings of over 88

Details for pellet boilers from 70 kW

Particle separator

Reduce your particulate emissions! Choose the right system for you from the various particle separator.

Firebed monitoring

Due to the exact, contactless ember bed height monitoring by means of sensors, the most effective combustion condition is achieved depending on the fuel quality. Your heating system always runs at the required output with optimum combustion values.

Step crusher grate

2 tiered rotating grates, one behind the other, can be moved independently of each other. The rear rotating grate opens, ash falls down, residual embers remain. When the boiler is cold, both grates open, cold ash and slag are disposed of. Crusher function’ breaks up slag.

Ash extraction into the box ( Eco-PK 70-330 kW)

An ash screw below the step crusher grate fills the box to the last corner, resulting in very long emptying intervals.

Ash extraction variants

Various options, whether ash transportation system or ash suction system are available with a filling volume of 240 lt or 300 lt.

Recirculation as standard

In order to counteract the tendency of the ash of very dry heating material or at a very low ash melting point, every Eco-HK is equipped with flue gas circulation as standard. The ash can then be disposed of without any problems.

Integrated return flow boost

An integratable return flow boost with energy-saving pump and motorised mixer is available as an accessory.

– Quick and easy installation

– Compact and cost-effective

News, References, Events & more

Discover the world of biomass and find out all the latest news about the heating manufacturer HARGASSNER. We offer solutions for a wide range of industries - from private households to agriculture & forestry to trade & industry.